-

Product Introduction

The visualized positive-pressure explosion-proof welding habitat independently developed by Welltech has an excellent reputation in the industry. It holds exclusive patents and its technology ranks among the international leading level. The operating principle is to use full-function detection equipment to detect hazardous gases, pressure, temperature, and humidity at the construction site (including both inside and outside the explosion-proof habitat). When abnormalities are detected, an automatic alarm is triggered to ensure the safety of the hot work environment during operation.

-

Design Highlights & Features

On-site assembly of explosion-proof joints eases operation. A full LCD screen shows all detection data, simple and intuitive. Mobile cart design enables single-person operation, cutting manual handling costs. Fully bonded fire-resistant tarpaulin (550-1100℃) is easy to set up with scaffolding. Intelligent tech connects up to 99 detector channels, with independent control via the dashboard.

-

Product Upgrade Service

Our welding habitat can use φ300-φ600 fans in parallel (calculated to meet on-site large-scale hot work). The largest habitat in use now is 10m × 40m × 7m, with 12 φ600 fans. Optional wireless function supports up to 2km distance, with disconnection alerts on the monitor. Battery-powered detectors last 30 days per charge. Our R&D team offers customized upgrades and on-site guidance per customer needs. T3-condition mobile air conditioners/heaters are also available, enabling temperature and air quality control inside the shelter at -20℃ to +60℃.

-

Difficulties of Hot Work Environments

Significant temperature fluctuations tend to exceed the tolerance of equipment or processes, impairing operational accuracy and safety. Welding or other operations generate flammable and explosive gases (e.g., acetylene), which are liable to ignite or explode upon contact with high temperatures or sparks. A large volume of welding fumes and metal dust is produced, contaminating the environment and endangering operators’ health.

-

Key Functions of Welding Habitats

Stable temperature control: Regulates internal temperature via an enclosed structure and ventilation system, minimizing external environmental interference. Explosion-proof protection: Maintains positive pressure inside the room to block external flammable/explosive gases from entering, while promptly expelling internal combustible gases to reduce explosion risks. Environmental purification: Equipped with dust and fume removal devices to filter welding-generated dust and harmful gases, ensuring operator health and compliance with environmental standards.

-

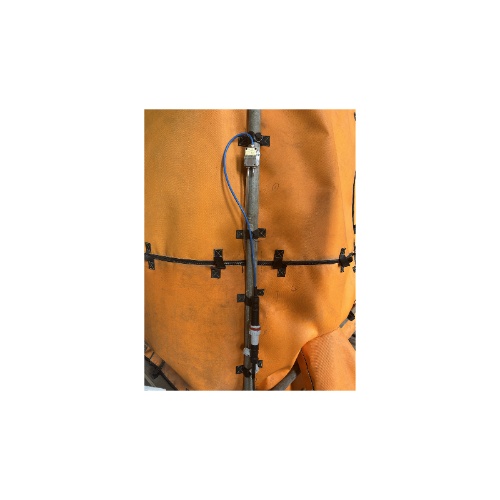

Gas Detector

This component is directly integrated into the fan and connected together with the fan through fast wiring and explosion-proof control box to achieve real-time signal transmission between the two.

-

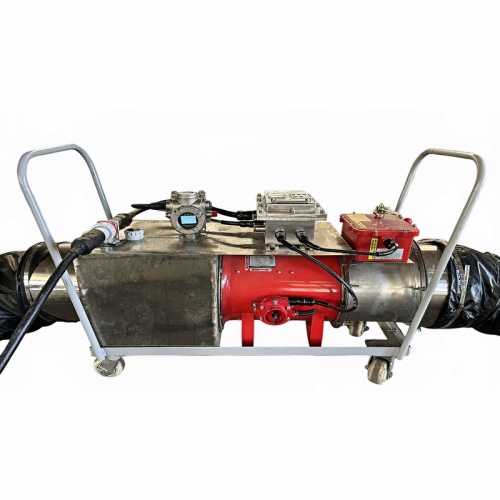

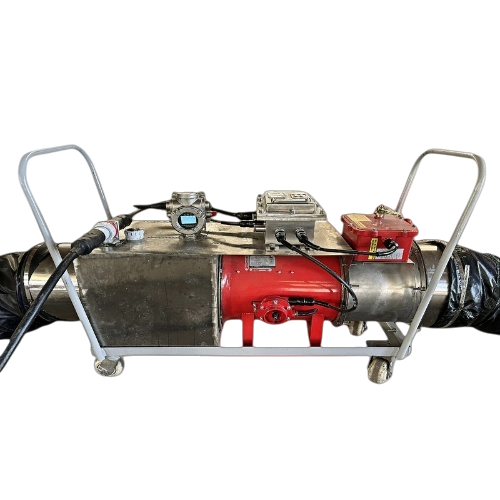

Explosion-Proof Fan

The explosion-proof fan is integrated with a combustible gas detector, a hydrogen sulfide detector, and an air damper, and is specifically designed to supply air to the welding habitat.

-

Ex Air Conditioner

The system uses ex air conditioners and fans operating in series. As the air supply core, the fan efficiently distributes the air conditioners’ cooling capacity to all areas, forming a cold air cycle and maintaining temperature within an appropriate range.

-

Ex Control Box

This excontrol box, holding an authoritative explosion-proof certificate, fully meets safety standards for flammable/explosive environments. It eliminates electrical component failure risks at the source, ensuring basic safety for the entire system’s stable operation.

-

Audible and Visual Alarm

This device uses a plug-in lamp structure—no complex tools or heavy disassembly needed. It also emits strong flash signals.