ATEX-Alarm System: Ex Safety Interlock Standards

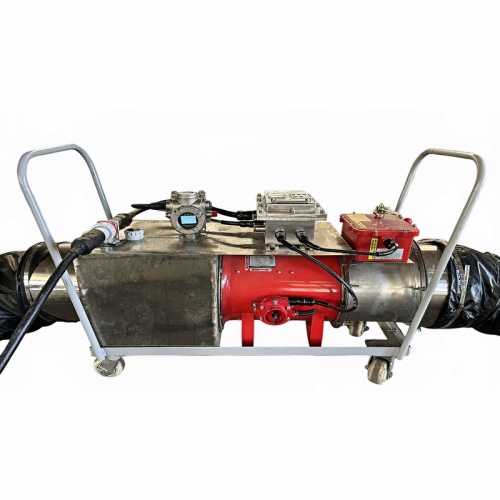

The risk of flammable gases in offshore oil engineering welding operations is extremely high, and the ATEX welding habitat alarm system for offshore projects serves as the core safety defense. This article discusses the triggering mechanisms of this system and the key points for explosion-proof compliance.

(1)Gas alarm

When the external environment or fan intake detects combustible gas concentration ≥5% LEL or hydrogen sulfide concentration ≥5 PPM, the audio-visual alarm activates. The system simultaneously cuts off power from both 380V and 220V external power supplies, halts operation of fans, air conditioning, and lighting equipment, and closes the air damper. During this process, the sensor continuously monitors gas levels until safety thresholds are re-established. A reset button on the control panel allows normal equipment startup upon confirming safe gas concentrations.

(2) Air pressure alarm

After 100 seconds of system startup, the differential pressure transmitter detects that the positive pressure in the welding room falls below 25Pa. The audio-visual alarm will trigger an audible and visual alert, while both the external 380V power supply and external 220V power supply will be disconnected. During this process, the differential pressure transmitter continuously monitors the room’s positive pressure. When the pressure regains a value of 25Pa or higher, the system automatically resets itself, and both external power supplies are restored.

(3) Temperature alarm

When the temperature reaches 60℃, the audio-visual alarm will trigger an audible and visual alert. The system will simultaneously cut off power from both the external 380V and 220V power supplies. During this process, the temperature sensor will continuously monitor the room’s temperature. If the indoor temperature drops below 60℃, the system will automatically reset itself, and the external 380V and 220V power supplies will resume operation.

(4) Air conditioning alarm

A. After the system starts, there is no display on the air conditioning panel. Check the air conditioning connection and zero condition;

B. When the air conditioner reports E4, it is a three-phase phase sequence error, and the three-phase phase sequence needs to be adjusted;

C. When the air conditioner is suddenly cut off during normal operation, it needs to wait for a period of time before starting normally;

(5) Communication alarm

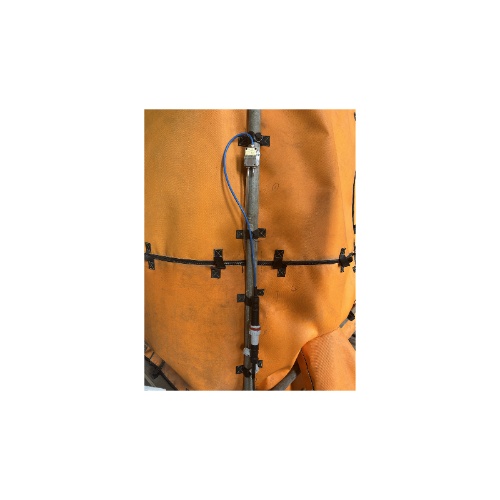

Install a dual-function probe (for hydrogen sulfide and combustible gases) at the air intake outlet of the fan. The probe communicates with the PLC via RS485. The control panel is equipped with a reset button. When communication fails, pressing this button will reset the system, allowing the PLC to reconnect with the probe. If communication cannot be restored after resetting, check whether the communication cable is disconnected.

(6) Disconnection alarm

The gas detection probe (external), temperature probe, and differential pressure transmitter are equipped with wire break alarms. When the equipment is disconnected from the PLC, the touchscreen displays real-time alarm notifications. Only after re-establishing the connection between the equipment and the PLC and pressing the reset button will the real-time alarm bar disappear on the touchscreen, while historical alarm information remains displayed.

(7) Overrange alarm

The gas detection probe (external), temperature probe, and differential pressure transmitter are equipped with wire break alarms. When the equipment is disconnected from the PLC, the touchscreen displays real-time alarm notifications. Only after re-establishing the connection between the equipment and the PLC and pressing the reset button will the real-time alarm bar disappear on the touchscreen, while historical alarm information remains displayed.