Installation Instructions: ATEX Welltech Welding Habitat

(1) Erection sequence

Measurement and location determination, design

Determine the location of fresh air collection, instrument and control equipment and the location of monitoring personnel.

Equipment placement, air duct and cable connections

Testing

Usage

(2) Measurement and location determination, design

Determine the construction site location according to requirements, and measure the length, width and height.

The chosen deck should be on a flat ground. Ensure that the ground is not sharp or raised.

Leave a 1*1 meter single room at the door as a buffer zone for gas leakage.

(3) Erection of welding room

According to the requirements, let the scaffolders build along the construction area. The interval between two poles of the scaffolding should not be more than 2 meters, otherwise the pressure in the shed is too large, which may cause the connection lock to be separated.

The fireproof shed is made of 1 meter by 1 meter or 1 meter by 2 meters. When installing, install the floor first, then the top, and finally the wall.

(4) Setting of fresh air position

The air inlet of the the duct should be located in the windward part of the platform deck, without any surrounding obstacles, so as to ensure fresh air in the air and minimize the possibility of mixing dangerous gases.

Air conditioning can be installed or not, depending on the weather.

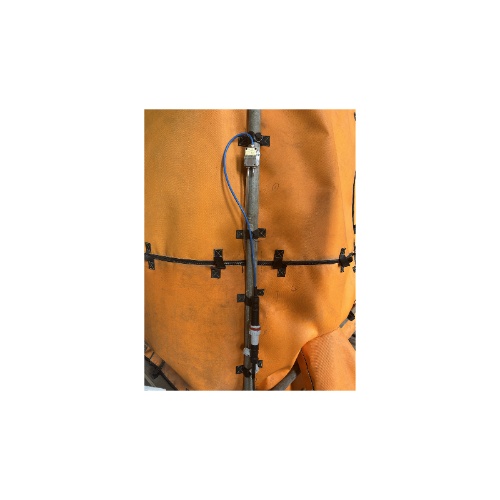

Before the detection of dangerous gas, after determining the location, the air inlet pipe is installed in a fixed position and fixed with iron wire to prevent shaking caused by strong wind.

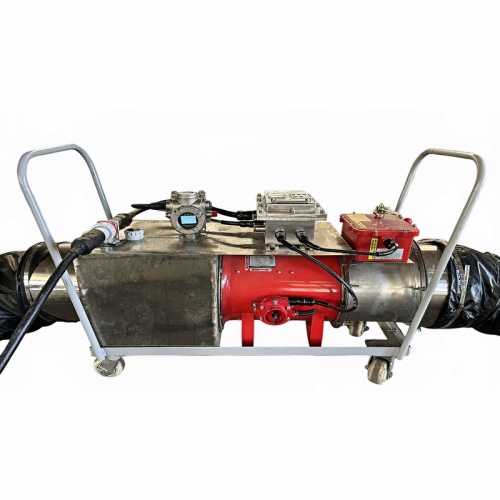

(5) Equipment placement and connection

Place gas detection equipment at the air inlet and fix it.

At the central control system level, and the fan and wind gate block, the guardian area is no more than 3 meters away from each other.

Connect air conditioning and explosion-proof control box, 380V.

Connect the fan to the explosion-proof control box, 220V, 24V.

Connect pressure differential transmitter, temperature transmitter, combustible gas detector, composite combustible gas detector, explosion-proof lamp, explosion-proof alarm 24V.

Connect the generator to the explosion-proof control box, 380V.

Connect the air inlet pipe, fresh air area and fan, wind gate and welding shed, φ300mm.

Connect the air duct to the welding shed φ100mm.

Connect the welding machine in the welding shed to the explosion-proof control box, 380V

Connect the manual tool in welding shed to explosion-proof control box, 220V.

Piezoelectric sensor, lighting lamp and temperature sensor are placed in the welding shed.

The composite combustible gas detector is located near the welding machine shed, no more than 1 meter away. If the gas near the welding machine shed exceeds the standard, it can trigger an alarm and shut down.

Visit one sound and light alarm monitor. Place one at a distance of 20 meters, which can warn other non-welding personnel if there is danger.

(6) Testing

Use can gas to spray from the air inlet pipe, test shutdown and alarm.

Use gas to test, shut down and alarm the combustible detector placed outside the explosion-proof welding shed.

Alarm and shutdown of insufficient positive pressure in test chamber.

Alarm and shutdown of temperature exceeding standard in test room.

Other tips

This welding system can be customized according to the volume of the welding machine shed, the number of construction electrical appliances and the temperature. The air conditioning capacity can be customized to meet the needs of different working conditions of customers. For any inquiries, please consult via email.