Differential Pressure Transmitter-Details and Parameters

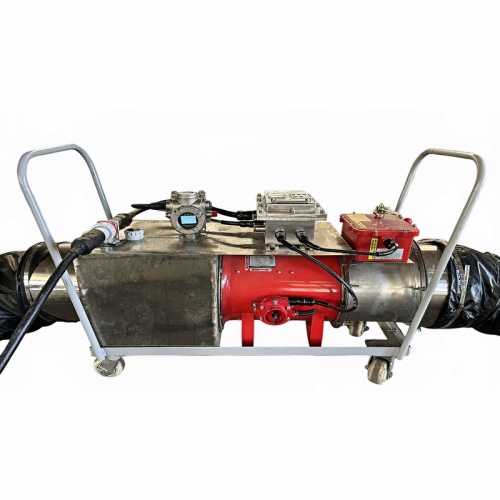

The differential pressure transmitter is an integrated industrial measuring instrument that integrates the functions of differential pressure sensing, signal processing, and standard signal output. Its core principle is to convert the pressure difference between two measured pressure sources into a physical deformation signal via its internal sensing element. The signal is then processed through circuits for amplification, filtering, and temperature compensation, and finally converted into industrial standard signals such as 4–20mA current or RS485 digital signal. These signals can be directly connected to automation control systems like PLC and DCS to achieve accurate monitoring and interlock control of differential pressure. For applications in hazardous environments such as explosion-proof positive pressure welding booths, the differential pressure transmitter must also be equipped with an explosion-proof structure compliant with ATEX/IECEx standards to ensure safe and stable operation in flammable and explosive areas.

Core Functions

Accurately monitor the air pressure difference between the inside and outside of the booth in real time, providing core data support for the positive pressure explosion-proof system.

Output standard industrial signals with strong anti-interference capability, supporting long-distance transmission and adapting to industrial automation control scenarios.

Interlock with the PLC control system to realize automatic adjustment of the positive pressure system, real-timely adjust the fan speed and control the on-off of the pressure relief valve according to the pressure difference changes, so as to maintain the safe micro-positive pressure inside the booth.

Be equipped with safety early warning and protection functions. When the pressure difference is lower than the safety lower limit or higher than the safety upper limit, it will trigger sound and light alarms in a timely manner; if the pressure difference remains abnormal, it will directly cut off the welding power supply, fundamentally preventing external flammable gases and dust from entering the booth and ensuring the explosion-proof safety of welding operations.

Working Principle

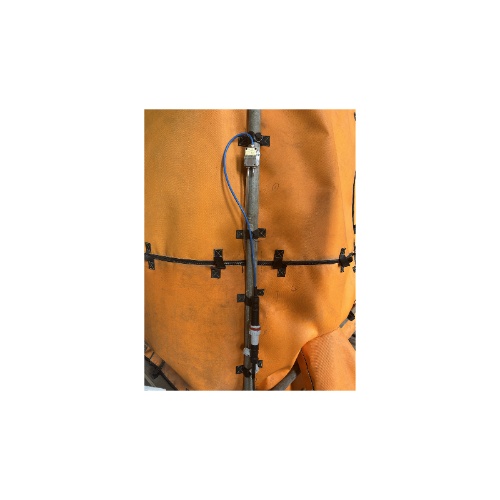

Two pressure sampling pipes are used to collect the air pressure inside and outside the welding booth respectively. The pressure difference between the two sides acts on the piezoresistive or capacitive sensing element inside the transmitter, which converts this pressure difference physical quantity into a weak millivolt-level voltage or frequency signal. Then the built-in signal processing unit amplifies, filters noise and performs temperature compensation on the original signal to eliminate measurement errors caused by welding vibration and ambient temperature changes. Finally, the optimized signal is converted into industrial standard signals such as 4–20mA current or RS485 digital signal, and transmitted to the PLC control system of the welding booth. The PLC then automatically executes interlock operations such as fan speed regulation, pressure relief valve on-off control or welding power cut-off according to the preset pressure difference thresholds.

Technical Parameters

Measuring Range: 0–200Pa; high-precision models can reach 0–100Pa.

Measurement Accuracy: ±0.5% FS ~ ±1% FS, ensuring the stability of pressure difference.

Explosion-Proof Rating: Ex d IIC T4 Gb (flameproof type).

Protection Rating: ≥IP66, suitable for resisting salt spray, humidity and dust erosion in outdoor and marine environments.

Output Signal: 4–20mA (industrial standard signal, compatible with PLC and digital display meters) or RS485 (supporting remote monitoring).

Response Time: ≤100ms, ensuring rapid triggering of interlock control when pressure difference fluctuates.

Operating Temperature: -40℃~+85℃, adapted to extreme temperature working conditions such as marine and polar regions.